Prototyping a product has been a traditionally costly, involved process—an engineering labor of love. 3D printing has steadily altered that reality, ushering in an era of possibility for the design industry in particular. Several companies, including Holly Hunt and Waterworks, are dabbling in the process to learn what works best for their product collections and design development.

With new opportunities to produce, designers are exploring 3D technology’s advantages. The ability to prototype with a higher degree of precision—and with materials that have corresponding physical properties to the final part—is just one of the benefits for design manufacturers conceiving new furniture pieces and other items from scratch.

“Using the 3D printer allows us to explore new shapes and new possibilities,” said Alberto Velez, Design Director at Holly Hunt. “The printer can do anything the computer can do, so we’re creating things that we couldn’t see and touch before. It really helps with the initial design process. It definitely opens the door for things we weren’t able to do before. It opens the mind and makes you think of different possibilities.”

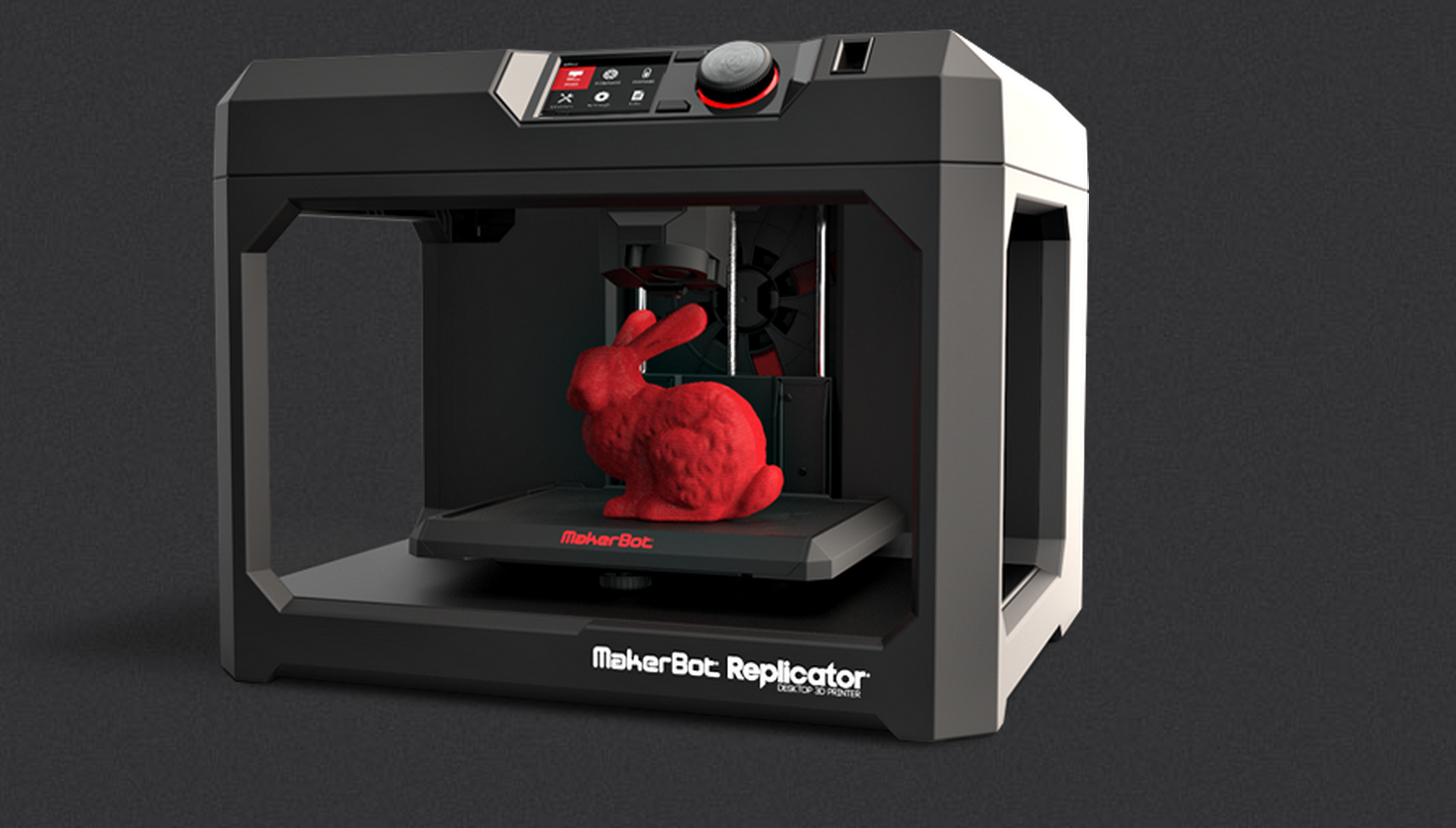

Alberto shared that Holly Hunt now uses an in-house 3D printer by Makerbot in the initial process of designing almost every product that the company creates. While the items are not replicated at full-scale, the mini-models that the printer produces allows the design team to see issues that may not be visible in a flat drawing, and they can address them right away.

Holly Hunt’s Pyrite Table prototype

“We are, however, able to create some parts at full-scale, like hardware and pulls for drawers,” said Alberto. “It’s excellent because you can really test how it feels on your hand. Then we can send it to the manufacturer who uses that plastic piece as the mold and will cast it in bronze, or whatever material we want to use. This removes the margin of error in that process—we are gaining more control and saving money in the process.”

While factors like lead times and business models have not been changed much by 3D printing technology, it is certainly changing the pace in which new designs are edited and presents a critical in-between step for designers before they put a piece into production.

“When we began using 3D printing, the equipment was very expensive and challenging to maintain,” said Peter Sallick, CEO of Waterworks. “We started using 3D printing out-of-house due to these restraints, but since the technology has evolved and become more affordable and easier to maintain, our team is able to benefit from this drastically. Today we print everything from faucets to robe hooks, to pot fillers and hardware pulls.”

Historically, 3D printing has been used for prototyping and this continues to be its primary role in design. As the technology begins to evolve more rapidly, 3D printing is becoming more accessible and could eventually play a larger role in the design world.